1. Set the heating temperature of the high-frequency furnace/medium-frequency furnace according to the product

2. The operator reasonably adjusts the feeding speed according to the production beat

1. Set the heating temperature of the high-frequency furnace/medium-frequency furnace according to the product

2. The operator reasonably adjusts the feeding speed according to the production beat

1. Fill in the corresponding specification table according to the type and specification of the raw material

2. The raw materials are painted with the corresponding colors according to the color of the steel material.

1. Fill in the corresponding specification table according to the type and specification of the raw material

2. The raw materials are painted with the corresponding colors according to the color of the steel material.

1. The blanking staff arranges blanking according to the blanking schedule

2. Fill in the process flow card according to the regulations and place it in each frame

1. The blanking staff arranges blanking according to the blanking schedule

2. Fill in the process flow card according to the regulations and place it in each frame

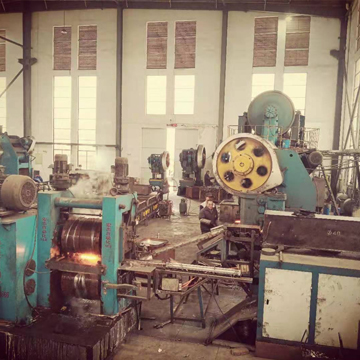

Products heated by high frequency furnace/medium frequency furnace flow into the roll forging machine

Products heated by high frequency furnace/medium frequency furnace flow into the roll forging machine

1. Products heated by high frequency furnace/medium frequency furnace flow into the roll forging machine

2. The roll forging product is put into the press to bend the billet

1. Put the deoxidized product into the pre-forging die

2. Press down the 630T electric screw press

1. Put the deoxidized product into the pre-forging die

2. Press down the 630T electric screw press

1. Put the pre-forged product into the precision forging die

2. Press down the 630T friction press

1. Put the precision forging product into the trimming die

2. Press the press button (trimming)

1. Put the precision forging product into the trimming die

2. Press the press button (trimming)

1. Put the plastic products into the plastic mold

2. Press the 1000T/400T pressure switch button

1. Put the plastic products into the plastic mold

2. Press the 1000T/400T pressure switch button